Address

shenzhen city,china

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Fire dampers are vital parts of any building’s fire protection system. Installed inside ductwork, they are designed to block the spread of flames and smoke during a fire. By acting as a barrier, fire dampers help isolate dangerous areas and protect spaces that may not yet be affected, allowing more time for evacuation and response.

Their core function is automatic closure when exposed to high temperatures. This action seals off airflow within the ducts, preventing smoke and fire from reaching other parts of the structure. There are two primary types of dampers: standard fire dampers, which close when heated, and fire smoke dampers, which also respond to smoke. Both are essential for meeting modern fire safety codes.

Fire dampers must comply with regulations. Manufacturers design them according to local standards, and regular inspections are legally required to ensure reliable performance. Working with a trusted fire damper supplier and following a consistent inspection checklist are key to keeping these systems effective.

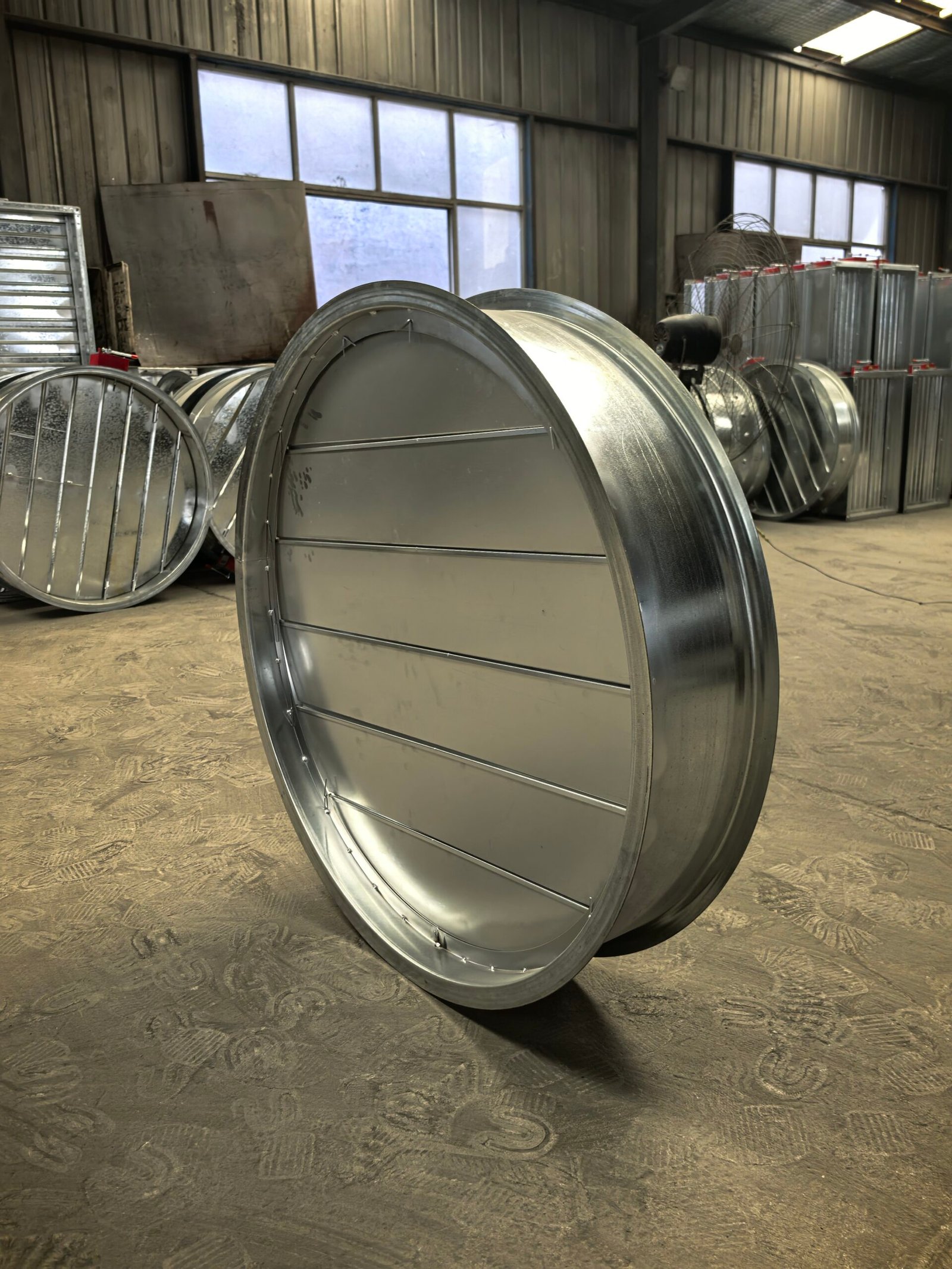

Fire dampers vary in design, depending on their function and where they’re used. Understanding each type is important when choosing the right fire safety solution for a building.

Dynamic Fire Dampers: These dampers stay open under normal airflow and automatically close during a fire. They’re often linked to fire alarm systems and are ideal for commercial settings where HVAC systems run continuously.

Static Fire Dampers: These close in response to heat but do not operate under airflow. Used in low-risk areas, they are simpler and more cost-effective but still provide essential compartmentalization during a fire.

Curtain Fire Dampers: Built like a physical curtain inside the duct, they drop down when triggered by heat or smoke. These are ideal for large, open spaces such as malls or warehouses.

Combination Fire/Smoke Dampers: These offer dual protection—blocking both flames and smoke. They’re used in buildings with complex air systems, offering complete fire control with easier installation and maintenance.

Each type serves a different need, and consulting a qualified fire damper supplier or manufacturer ensures the right choice is made for the application.

Dynamic fire dampers operate effectively under airflow. Unlike static types, they are designed to remain open during regular HVAC operation and close only when needed—such as when smoke or high temperatures are detected.

These dampers use sensors to detect pressure differences or heat. Once activated, they shut quickly to contain the fire. Their ability to handle airflow makes them ideal for large, busy buildings like hospitals or office towers.

Using dynamic dampers also helps maintain air quality and comfort while meeting strict fire codes. Regular fire damper inspections are critical to verify performance and ensure all parts are working correctly.

Static fire dampers stay in place until a fire triggers their response. Built with heat-sensitive elements, they close tightly when temperatures rise, preventing the fire from spreading through the ductwork.

Commonly used in smaller or lower-risk areas, static dampers don’t adjust to airflow, which means they work best in areas where HVAC activity is minimal. Their design includes blades or panels that snap shut during a fire event.

While simpler than dynamic versions, static dampers are just as vital. They must be properly installed and checked regularly using a fire damper inspection checklist to ensure readiness.

Curtain fire dampers are specially designed for vertical ducts or large openings in walls and ceilings. When triggered by heat or smoke, they drop down like a curtain to block off the airflow path.

They’re often found in high-rise buildings, airports, and shopping centers. Many are motorized to ensure quick closure when connected to fire detection systems.

To meet regulations, curtain dampers must be UL listed or meet NFPA standards. Their fast action and wide coverage make them critical in buildings where compartmentalization is key to preventing fire spread.

These multi-functional dampers offer the highest level of protection. They not only stop flames from moving through ducts but also detect and block smoke.

Equipped with both heat and smoke sensors, they provide quick, automatic response. They’re especially useful in public buildings, residential complexes, and industrial environments.

By combining two safety functions in one unit, they reduce installation time and simplify maintenance. Many modern versions are motorized for even faster operation. Routine inspections ensure they remain compliant and effective under emergency conditions.

Fire dampers work using heat-activated mechanisms. Most use a fusible link—a small metal piece that melts at a set temperature (usually 165°F or 74°C). When it melts, it releases the damper blades, which swing shut to block the duct.

Other dampers use electric motors or actuators, triggered by fire alarms or smoke detectors. These motorized dampers close more quickly and are better suited for complex systems with high airflow.

Regardless of type, the goal is the same: stop fire and smoke from spreading. Regular fire damper testing ensures these mechanisms function properly, especially in emergencies.

Installing fire dampers correctly is vital. They must be placed where ducts pass through fire-rated walls and follow all local building codes. Working with certified fire damper manufacturers and experienced installers helps ensure compliance.

Before installation, assess your HVAC layout. Choose the right damper type—static, dynamic, or combination—based on airflow needs and fire risk level.

Maintenance is just as important. Use a fire damper inspection checklist to track performance. Inspections should cover:

Blade movement

Fusible link condition

Obstructions or damage

Signs of corrosion

Some dampers need cleaning or lubrication. All checks must be logged for legal compliance and safety assurance.

Fire dampers are essential for fire safety in any modern building. They help stop the spread of smoke and flames, protect occupants, and ensure compliance with fire regulations.

Understanding the different types—dynamic, static, curtain, and combination—allows building managers to choose the right solution. When installed and maintained properly, these systems serve as reliable defenses during emergencies.

By working with trusted fire damper suppliers and performing regular inspections, businesses can strengthen their fire protection plans and keep buildings safe.

What is the main purpose of a fire damper?

A fire damper is designed to prevent the spread of flames and smoke through HVAC ductwork during a fire. It automatically closes when triggered by high temperatures, helping to contain the fire and protect building occupants.

What are the different types of fire dampers?

The main types include static fire dampers, dynamic fire dampers, curtain fire dampers, and combination fire/smoke dampers. Each serves specific use cases based on airflow, fire risk, and building layout.

How do fire dampers work?

Most fire dampers use a fusible link that melts at around 165°F, releasing a mechanism that closes the blades. Motorized or smoke-activated dampers use sensors and actuators for faster response.

Where should fire dampers be installed?

Fire dampers should be installed where HVAC ducts pass through fire-rated walls, floors, or barriers. Placement must comply with local fire codes and building standards.

How often should fire dampers be inspected?

Inspections are typically required annually, though some jurisdictions mandate more frequent checks. An inspection checklist should include testing for blade movement, fusible link integrity, and signs of damage or obstruction.

Can one damper block both fire and smoke?

Yes. Combination fire/smoke dampers are designed to block both flames and smoke. They are ideal for areas that require comprehensive protection with fewer components.

What is the difference between static and dynamic fire dampers?

Static dampers are for systems without airflow during fire, while dynamic dampers operate in systems with active airflow. Dynamic dampers are better for commercial HVAC systems that run continuously.

Do fire dampers require power to function?

Standard fire dampers with fusible links do not require power. Motorized fire dampers, however, need power to operate sensors and actuators for automatic closure.

https://en.wikipedia.org/wiki/Fire_damper

Introduction to Fire Dampers Fire dampers are vital parts of any building’s fire protection system. Installed inside ductwork, they are designed to block the spread of flames and smoke during a fire. By acting as a barrier, fire dampers help isolate dangerous areas and protect spaces that may not yet be affected, allowing more time…

What Are Gravity Fire Dampers? Gravity fire dampers are small but essential fire safety tools. When a fire breaks out, these dampers stop smoke and flames from spreading through the air ducts. Instead of using electricity, they work through a simple process. Once the temperature rises, a heat-sensitive link melts. As a result, the damper…